Manufacturing

Have an existing component you need machined? We are here to help. We are familiar with numerous design standards including but not limited to ASME and ISO. Whether you have a solid model, a napkin sketch, or a set of drawings, we can aid in making your parts real.

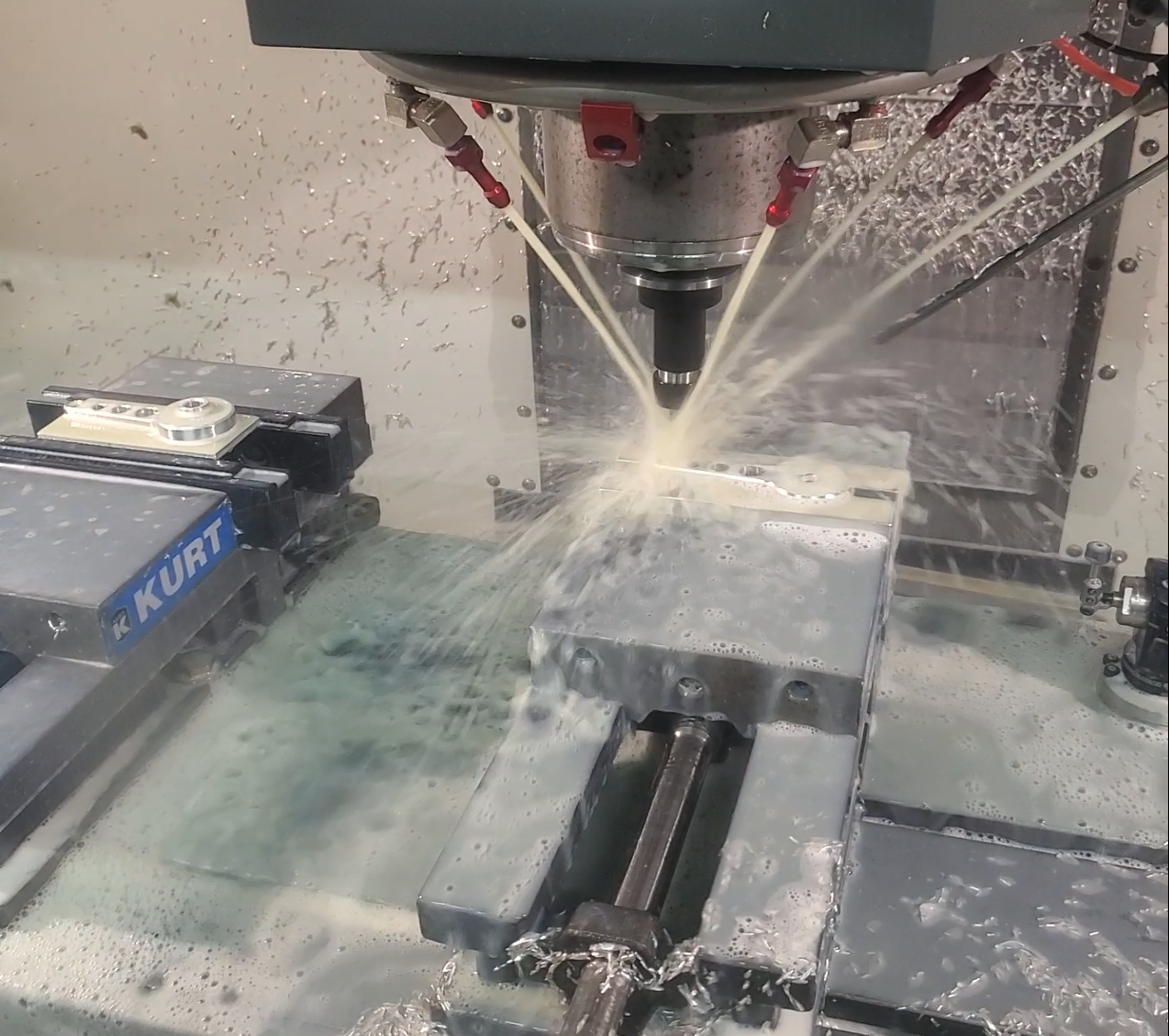

Rocan Motor Company utilizes modern, Industrial-level CNC machinery, in addition to a wide range of manual machines. We run numerous turning and milling centers, with simultaneous 4 axis high-speed machining capabilities. We specialize in design for manufacturing (DFM), allowing our clients to rapidly move from prototyping to mass production, with minimal rework.

By keeping manufacturing and inspection in house we assure the absolute tightest process control possible. We strive to maintain ISO:9001 Compliance. Our machines and equipment are carefully maintained and regularly inspected, assuring that our end product always meets our exceedingly high standards.

HAAS VF-2SS CNC Mill

Work Envelope of 30” by 16” by 20”

12,000 RPM Spindle allowing for efficient machining of small features

4 axis, allowing for complex parts to be manufactured in a minimal number of setups

HAAS HL-1 CNC Lathe

Max Turning Dia: 10"

Max Turning Length: 20"

Max Swing: 20"

Bar Pulling Capabilities up to 1.75"

Collet Chuck and 3 Jaw Chuck

Envisiontec Perfactory DLP Resin Printers

Two Industrial Grade Resin Printers

Build Volume of160 x 100 x 180 mm at 62 Micron Voxel Size

Build Volume of 192 x 120 x 180 mm at 75 Micron voxel size

Variety of materials available, allowing for rapid production of extremely fine detail parts such as electrical connectors and other plastics

Ability to create parts for metal casting, high temperature use, resistance to a wide variety of chemicals and petroleum products.